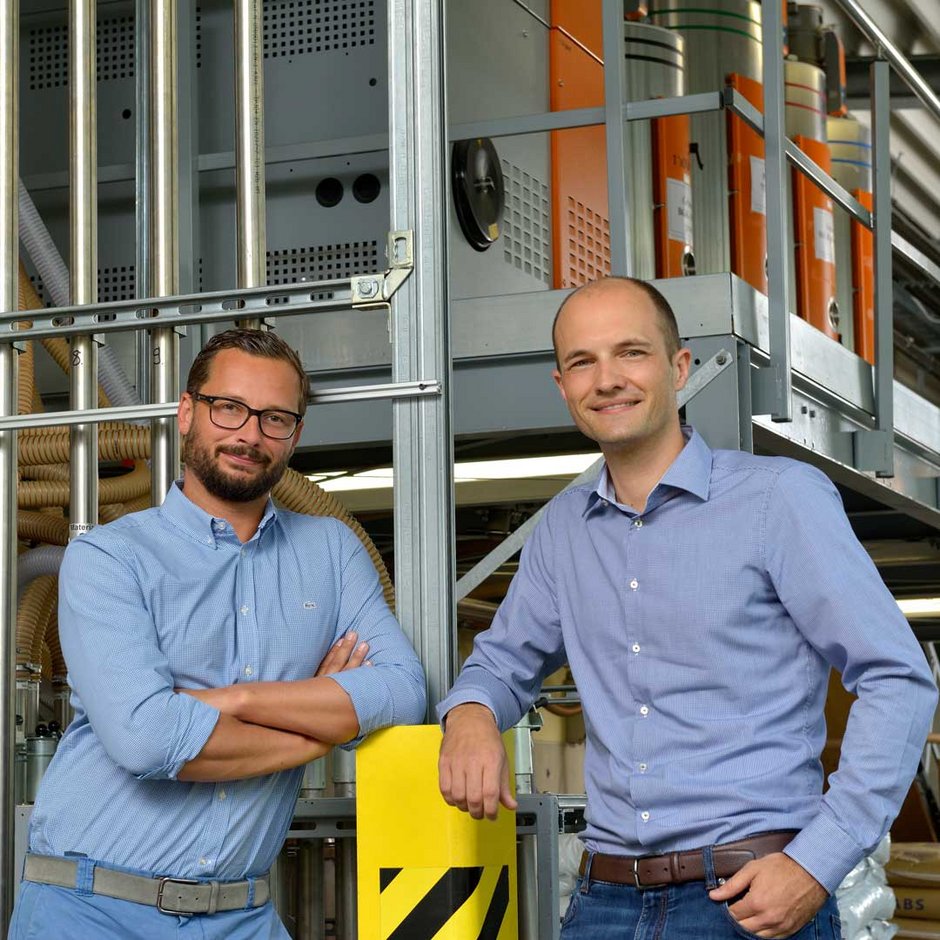

The company was founded in 1903. Continually expanding since then, the constantly modernised family-run company is now managed in its fourth generation by Christoph and Thomas Allgaier. Even though the fathers are still present in the company, they handed over management to the two cousins two years ago. A successful change-over, as the two emphasise. It is indeed the smooth transitions and further developments which characterise the company. It is exactly this which is reflected in the company history, which – especially in the last 40 years – is also a history of the co-operative partnership first with colortronic, then with motan and recently with motan-colortronic.