Strategic change at motan: Swiss sales company motan swiss ag to be handed over

Global swift Product Training

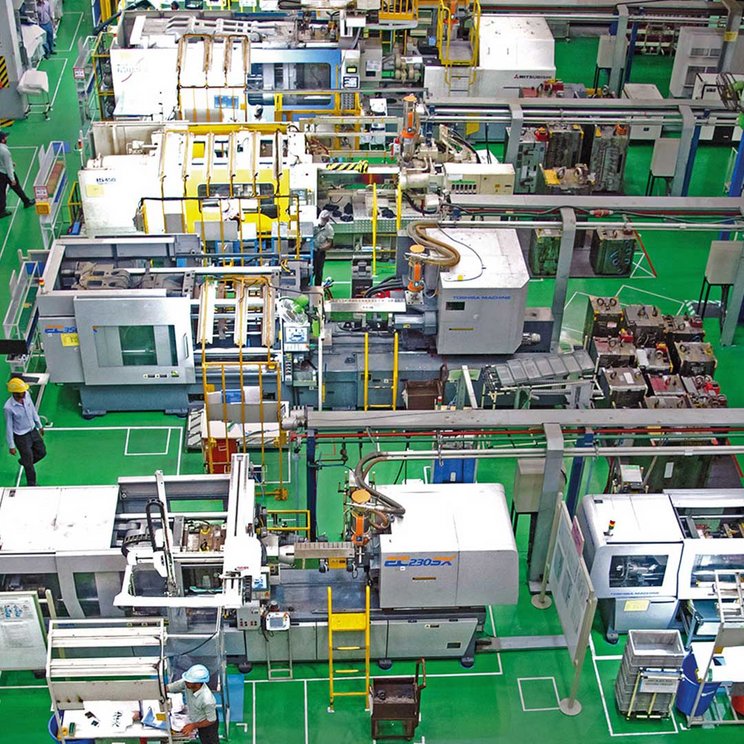

German Engineering meets Indian Passion – Inauguration of our new Operations Centre in Chennai, India

From Waste to Wealth: Plastics in a Circular Economy – Sustainable Solutions and Innovation for a Greener Future

The motan foundation supports everwave - A tricycle for Cambodia

motan group again awarded as world market leader

- Strategic change at motan: Swiss sales company motan swiss ag to be handed over

- Global swift Product Training

- German Engineering meets Indian Passion – Inauguration of our new Operations Centre in Chennai, India

- From Waste to Wealth: Plastics in a Circular Economy – Sustainable Solutions and Innovation for a Greener Future

- The motan foundation supports everwave - A tricycle for Cambodia

- motan group again awarded as world market leader